PE Film

Polyethylene Film (LLDPE, LDPE, HDPE Film)

Our mill use only world-class technology for LLDPE lamination film. The facility is located in high standard clean room to provide the best quality of lamination film. With the 3-layer co extrusion extruded, we produce better sealing strength film, high clarity film and better cost saving for customers. In last quarter of 2013, a new 7 layers co extrusion line has been installed to cope with market demand and its business expansion.

LLDPE FILM - C4 & C8 |

|

Thickness (micron) |

20 - 160 mic |

|

Characteristics |

- Self sealing - solve tearing, sealing and other problems

- Surface treated - excellent lamination strength

- Cross-linked - moisture / vapor barrier and physical damage resistant

- Cost saving - engineering customiszabel cost saving

|

Application |

- Retort Grade

- Antifog Grade

- Metallocene Grade

- Easy Peel Grade

- Metallized LLDPE

- Special Grade for grease proof packaging(Oil packing)

- EMAP Film (Equilibrium Modified Atmosphere Packaging)

|

|

LLDPE STRETCH FILM (VIRGIN GRADE AND RECYCLE GRADE) |

|

Thickness (micron) |

12mic - 140 mic |

|

Product Type |

- Baby roll

- Hand roll

- Machine roll

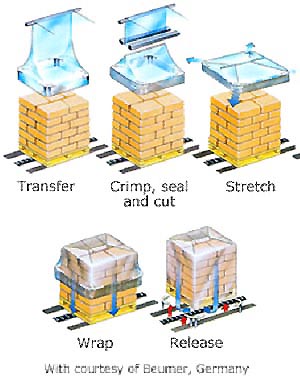

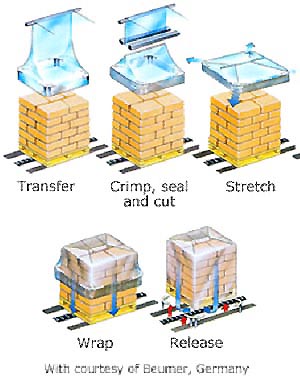

- Stretch Hood Packaging

|

|